Over 80 million people in the Democratic Republic of Congo (DRC) depend on the trees from the Congo rain forest for charcoal fuel as the primary source for cooking as other sources of fuel like electricity or natural gas are either unavailable, inconsistent, or very expensive. Most of the charcoal used in Kinshasa are made in villages hundreds of miles away from the city. Accessing these villages can be very difficult, if not impracticable, especially during the rainy season due to road conditions. Understandably, while the demand for charcoal remains high, supply decreases during the rainy season (Sep – May) driving the cost of charcoal higher.

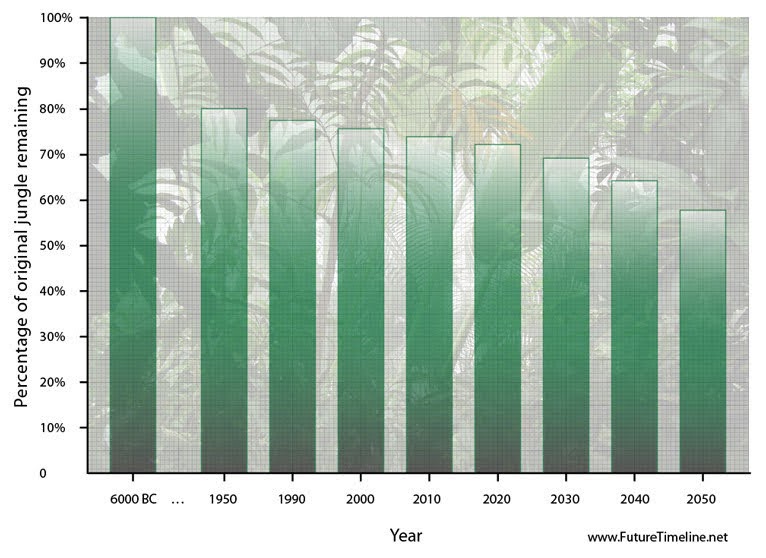

Deforestation and Greenhouse effects

DR Congo has been losing its rain forest at an alarming rate of about 1,235,527 acres (almost the size of Delaware, US) each year, and one of the main causes is the manufacturing of wood charcoal. Charcoal in DR Congo are primarily made from trees, which are cut, dried, and carbonized in ovens made from clay or mud. This practice has largely contributed to the deforestation of the world’s second-largest rain forest (after Amazon in Brazil) and greenhouse gas emissions that cause global warming.

Health Concerns

The current process of making charcoal generates incombustible materials like benzene, formaldehyde, acrolein, and fine particle matters or MP2.5 that are harmful to human health, especially those individuals with lung disease, diabetes, obesity and asthma; small children or older adults are also highly vulnerable.

The Shilo Foundation Bio Charcoal Project can help reduce the greenhouse effects and provide alternative solutions to the current practice of burning wood. Tons of biomass wastes that are widely available throughout the city can efficiently be converted to produce charcoal briquettes.

Tons of wastes have been accumulated over decades and are found on the streets of Kinshasa, clogging drainage systems, and creating a breeding environment for mosquitos that spread malaria. Malaria is the number one killing disease in Africa, and the city does not have waste management plan capable of treating the wastes created by the 80 million people living there, therefore lacking the curtailment of the risk of malaria infection.

Opportunities

Most of the materials found in these wastes can be used to make bio charcoal: coffee grinds, rice straw, rice husk, coconut shell, sugar cane bagasse, bamboo, recycled paper, corn stover, groundnut shell, peanut shell, cardboard, dried animal droppings, dried human wastewater sewage, any vegetable or bio matter, etc.

Cardboard Waste

Coconut Shells

Rice Husks

Palm Kernel Shells

Bamboo

This project offers a unique opportunity to transform most solid waste into a cooking fuel, charcoal briquettes. It also offers a very unique opportunity to provide employment to thousands of young men and women, who (Kuluna) roam the towns of Kinshasa stealing, robbing, and attacking the population just to survive. With an abundance of raw materials available in Kinshasa, this project can provide a constant supply of cooking charcoal briquettes at a relatively cheaper price. This project will also help protect the DRC rain forest, reduce the greenhouse effects and the health risks associated with materials combustion, eliminate wastes while cleaning the city while also reducing the risk for malaria. Not to mention, the provision of job availability will reduce the crime level by keeping these young men and women employed.

Making Briquettes

Pretreatment of materials: Raw materials have to be less than 20% humid and crushed at 50mm or less prior to processing. The charcoal machine needs to be equipped with both dryer and crusher to improve the efficiency.

Carbonization: Dried and crushed raw materials are conveyed into a carbonization machine where they can be distilled and converted into carbon with a temperature of 840-950 °F (450-510 °C).

Making briquettes: carbonized materials need to cooled off and crushed again before being pressed into briquettes. This process may require mixing of the carbonized materials with some adhesive substance as they are going into the pressing machine. Briquettes must be allowed to dry by heating them to 275 °F (135 °C) for about three to four hours.

Project implementation

- Establish waste collection points at strategic locations across the city of Kinshasa.

- Hire men and women who need jobs to collect raw materials for briquettes.

- Build a warehouse where waste materials will be received, processed and briquettes stored

- Purchase bio charcoal making equipment and packaging equipment

- Purchase vehicles to transport raw materials and briquettes

Implementation Cost

The implementation cost will include the cost of the equipment, equipment shipment, building construction, vehicles purchase, and startup price. The charcoal machine alone ranges from $58K to $128K depending on production capacity and efficiency. The entire project may cost over $450K, however, the return on the investment far surpasses the cost to implement.

References:

- https://bestonpyrolysisplant.com/biomass-carbonation-machine/

- https://briquettesolution.com/a-briquette-solution-for-turning-biomass-to-charcoal/

- https://www.wri.org/blog/2017/10/river-lined-smoke-charcoal-and-forest-loss-democratic-republic-congo

- https://www.climatelinks.org/photo-contest/gallery/sustainable-charcoal-mampu-democratic-republic-congo

- https://observers.france24.com/en/20180612-congolese-student-eco-friendly-charcoal

- https://www.alibaba.com/product-detail/Factory-direct-sale-price-roller-press_60756575182.html?spm=a2700.details.deiletai6.10.1bef3c2exph9Mg

- https://rtd.rt.com/stories/congo-kuluna-youth-gangs/